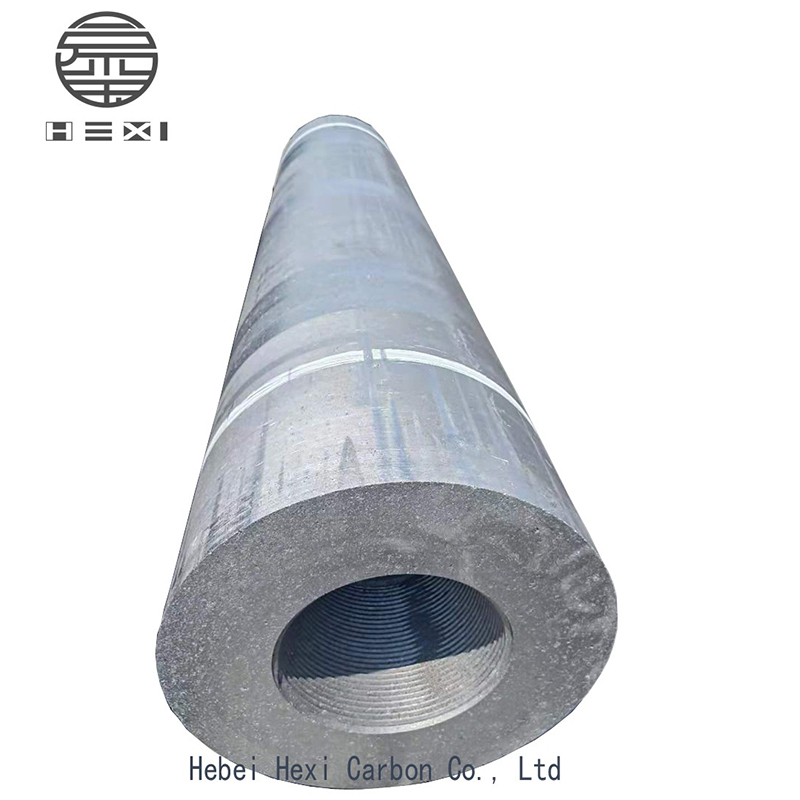

450mm siab zog graphite electrod

HP graphite electrode feem ntau yog ua los ntawm roj av coke thiab koob coke, Nws muaj peev xwm nqa tau qhov ceev tam sim no 18-25A / cm2. Nws yog tsim los rau siab zog hluav taws xob arc rauv steel-ua.

| Sib piv Technical Specification rau HPGraphite electrode18 ″ | ||

| Hluav taws xob | ||

| Yam khoom | Chav tsev | Supplier Spec |

| Cov yam ntxwv ntawm tus ncej | ||

| Nominal Dia | mm | 450 |

| Max Txoj kab uas hla | mm | 460 |

| Min Dia | mm | 454 ib |

| Nominal Ntev | mm | 1800-2400 Nws |

| Max Ntev | mm | 1900-2500 Nws |

| Min Ntev | mm | 1700-2300 Nws |

| Kev ceev ceev | g/cm3 | 1.68-1.73 Nws |

| transverse zog | MPa | ≥11.0 |

| Young' Modulus | GPa | ≤ 12.0 |

| Tshwj xeeb Resistance | µ Ωm | 5.2-6.5 |

| Qhov siab tshaj plaws tam sim no | KA/cm2 | 15-24 |

| Lub peev xwm nqa tam sim no | A | 25000-40000 |

| (CTE) | 10-6 ℃ | ≤ 2.0 |

| cov ntsiab lus tshauv | % | ≤0.2 |

| Cov yam ntxwv ntawm lub txiv mis (4TPI / 3TPI) | ||

| Kev ceev ceev | g/cm3 | 1.78-1.83 Nws |

| transverse zog | MPa | ≥22.0 |

| Young' Modulus | GPa | ≤ 15.0 |

| Tshwj xeeb Resistance | µ Ωm | 3.5-4.5 |

| (CTE) | 10-6 ℃ | ≤1.8 |

| cov ntsiab lus tshauv | % | ≤0.2 |

Txoj kev txo cov electrode noj

Nyob rau hauv xyoo tas los no, nrog rau kev loj hlob ntawm Tuam Tshoj txoj kev lag luam hluav taws xob hluav taws xob, nrog rau cov kev xav tau rau kev txuag hluav taws xob thiab kev txo qis cov kws tshaj lij thiab cov kws tshawb fawb hauv tsev thiab txawv teb chaws xaus qee qhov kev ua tau zoo raws li hauv qab no:

1.Anti-oxidation mechanism ntawm dej tsuag graphite electrode

Los ntawm kev sim kev tshawb fawb, tshuaj tsuag tshuaj tiv thaiv oxidation ntawm cov electrodes tau ua pov thawj zoo dua nyob rau hauv nres ntawm sab oxidation ntawm graphite electrode, thiab lub peev xwm los tiv thaiv oxidation yog nce 6-7 zaug. Tom qab siv txoj kev no, kev noj cov electrode tau poob mus rau 1.9-2.2kg smelting ib tuj hlau.

2.Hollow electrode

Nyob rau hauv xyoo tas los no, Western Europe thiab Sweden tau pib siv hollow electrodes hauv kev tsim cov ferroalloy ore furnaces. Hollow electrodes, lub tog raj kheej zoo, feem ntau yog khoob hauv ntim nrog cov roj inert. Vim lub hollowness, qhov ci ci tau zoo tuaj thiab ua rau lub zog electrode siab dua. Feem ntau hais lus, nws tuaj yeem txuag hluav taws xob los ntawm 30% -40%, mus txog 50% feem ntau.

3.DC arc rauv

DC hluav taws xob arc rauv yog ib yam tshiab ntawm smelting hluav taws xob arc rauv tshiab tsim nyob rau hauv lub ntiaj teb no nyob rau hauv xyoo tas los. Los ntawm cov ntaub ntawv luam tawm txawv teb chaws, DC arc rauv yog ib txoj hauv kev zoo tshaj plaws los txo cov electrode noj. Feem ntau, electrode noj yuav txo tau li ntawm 40% mus rau 60%. Raws li cov lus ceeb toom, graphite electrode noj ntawm qhov loj-scale DC ultra-siab zog hluav taws xob rauv tau raug txo mus rau 1.6kg / t.

4.Electrode nto txheej tshuab

Electrode txheej tshuab yog ib qho yooj yim thiab siv tau zoo los txo cov electrode noj, feem ntau tuaj yeem txo cov electrode noj li ntawm 20%. Feem ntau siv electrode txheej cov ntaub ntawv yog txhuas thiab ntau yam khoom siv ceramic, uas muaj zog oxidation tsis kam ntawm qhov kub thiab txias thiab tuaj yeem txo cov oxidation noj ntawm electrode sab saum npoo. Cov txheej txheem ntawm electrode txheej yog tsuas yog txau thiab sib tsoo, thiab nws cov txheej txheem yog yooj yim thiab siv tau yooj yim. Nws yog txoj kev siv ntau tshaj plaws los tiv thaiv electrodes.

5.Impregnated electrode

Dip electrodes hauv tshuaj lom neeg ua rau muaj kev sib cuam tshuam ntawm cov electrode nto thiab cov neeg ua haujlwm los txhim kho cov electrode tsis kam mus rau qhov kub thiab txias oxidation. Cov electrodes no tuaj yeem txo cov electrode noj li ntawm 10% mus rau 15%.