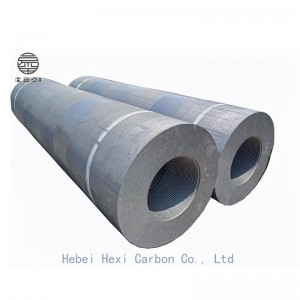

400 UHP graphite electrode

Graphite electrodes feem ntau yog siv rau hauv cov txheej txheem steelmaking. Hlau seem tau yaj nyob rau hauv ib qho hluav taws xob arc rauv thiab rov ua dua. Raws li ib yam ntawm cov neeg xyuas pib, lawv yog ib qho tseem ceeb ntawm cov khoom no

UHP graphite electrode feem ntau yog ua los ntawm cov koob zoo coke, thiab dav siv nyob rau hauv ultra siab zog hluav taws xob arc rauv.Nws muaj peev xwm nqa tau qhov ceev tam sim no ntau dua 25A / cm2.

| Kev sib piv kev qhia tshwj xeeb rau UHP Graphite Electrode 16 " | ||

| Hluav taws xob | ||

| Yam khoom | Chav tsev | Supplier Spec |

| Cov yam ntxwv ntawm tus ncej | ||

| Nominal Dia | mm | 400 |

| Max Txoj kab uas hla | mm | 409 ib |

| Min Dia | mm | 403 |

| Nominal Ntev | mm | 1600/1800 Nws |

| Max Ntev | mm | 1700/1900 Nws |

| Min Ntev | mm | 1500/1700 Nws |

| Kev ceev ceev | g/cm3 | 1.68-1.73 Nws |

| transverse zog | MPa | ≥12.0 |

| Young' Modulus | GPa | ≤ 13.0 |

| Tshwj xeeb Resistance | µ Ωm | 4.8-5.8 |

| Qhov siab tshaj plaws tam sim no | KA/cm2 | 16-24 |

| Lub peev xwm nqa tam sim no | A | 25000-40000 |

| (CTE) | 10-6 ℃ | ≤1.2 |

| cov ntsiab lus tshauv | % | ≤0.2 |

| Cov yam ntxwv ntawm lub txiv mis (4TPI) | ||

| Kev ceev ceev | g/cm3 | 1.78-1.84 Nws |

| transverse zog | MPa | ≥22.0 |

| Young' Modulus | GPa | ≤ 18.0 |

| Tshwj xeeb Resistance | µ Ωm | 3.4 ~ 4.0 |

| (CTE) | 10-6 ℃ | ≤1.0 |

| cov ntsiab lus tshauv | % | ≤0.2 |

Cov txheej txheem tsim khoom

Graphite electrode feem ntau yog ua los ntawm cov roj av coke thiab rab koob coke, sib xyaw nrog cov thee suab, tau txais los ntawm cov txheej txheem ntawm calcinations, kneading, sib sau, ci, graphitizing thiab machining, thaum kawg los ua cov khoom. Nov yog qee cov lus piav qhia rau qee cov txheej txheem tsim khoom:

Kneading: stirring thiab sib tov ib tug npaum li cas ntawm carbon hais thiab hmoov nrog ib tug npaum li cas ntawm binder ntawm ib tug tej yam kub, txheej txheem no hu ua kneading.

Kev ua haujlwm ntawm kneading

① Sib tov txhua yam ntawm cov ntaub ntawv raw khoom sib npaug, thiab tib lub sijhawm ua cov khoom carbon cov khoom sib txawv ntawm qhov sib txawv me me sib xyaw ua ke thiab sau, thiab txhim kho qhov sib tov sib xyaw;

② Tom qab ntxiv cov asphalt, muab tag nrho cov khoom sib xyaw ua ke.

③Ib co thee pitches nkag mus rau hauv cov voids sab hauv, uas ntxiv txhim kho qhov ceev thiab adhesion ntawm cov muab tshuaj txhuam.

Kev sib sau: Cov pa roj carbon monoxide kneaded yog extruded rau hauv lub cev ntsuab (los yog cov khoom ntsuab) nrog rau qee yam duab, qhov loj me, ntom thiab lub zog hauv cov khoom siv molding. Cov tshuaj txhuam hniav muaj cov yas deformation nyob rau hauv lub zog sab nraud.

Roasting kuj hu ua ci, Nws yog kev kho kub kub, ua rau cov pa roj carbonized rau coke tsim, uas sib sau ua ke cov carbonaceous aggregates thiab hmoov hais ua ke nrog cov neeg kho tshuab siab zog, qis zog, zoo thermal stability thiab tshuaj stability.

Secondary roasting yog ci ib zaug ntxiv, ua rau lub suab nkag mus rau carbonized. Electrodes (txhua yam tshwj tsis yog RP) thiab cov txiv mis uas yuav tsum tau muaj ntau dua yuav tsum tau muab ob-ci, thiab txiv mis peb-dip plaub-ci los yog ob-dip peb-ci.